- Jun 5

- 2 min

Ecogate Confirmed as Donaldson’s Official Supplier

- May 30

- 5 min

What Is Not Measured Cannot Be Controlled: How Ecogate greenBOX Measures Air Velocity and Air Volume

- May 15

- 2 min

One Year On: Celebrating the Revolutionary "Adelie" greenBOX Control System Unveiled at Ligna

- May 14

- 5 min

Increase System Performance with On-Demand Dust Collection

- May 10

- 2 min

greenBOX Unboxed i4: Accessing greenBOX User Interface on Desktop or Tablet

- Apr 30

- 4 min

Advanced Functionality in Ecogate's Smart Gates

- Apr 25

- 2 min

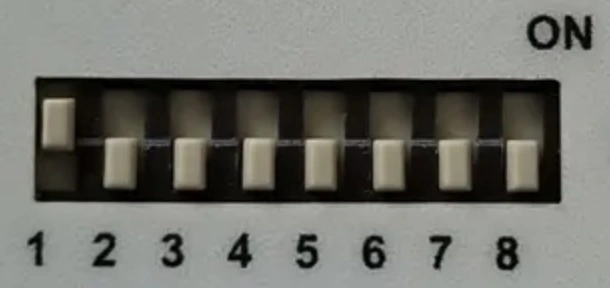

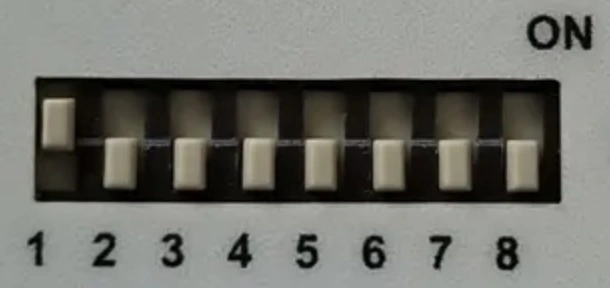

greenBOX Unboxed i3: Streamlined Installation with Automatic Modbus Address Assignment

- Apr 11

- 2 min

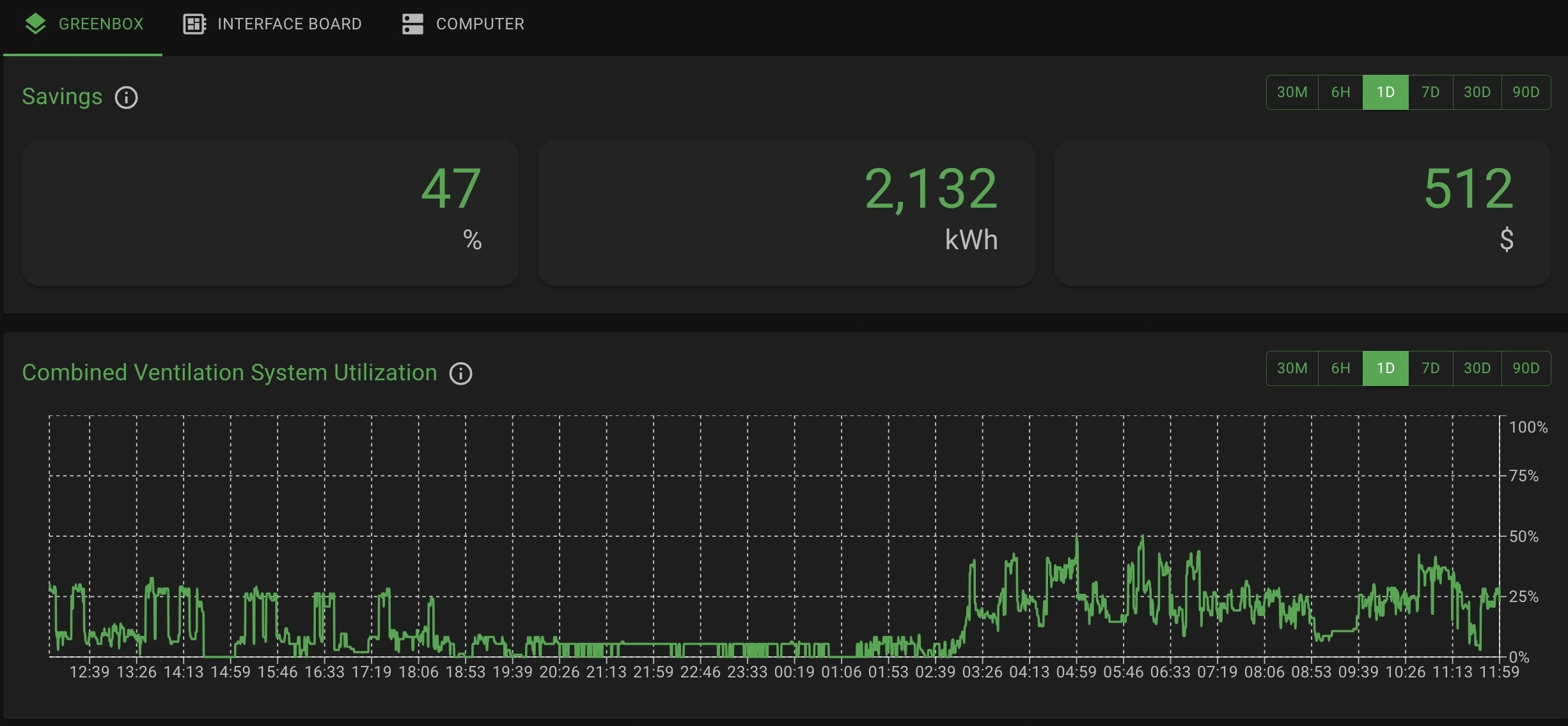

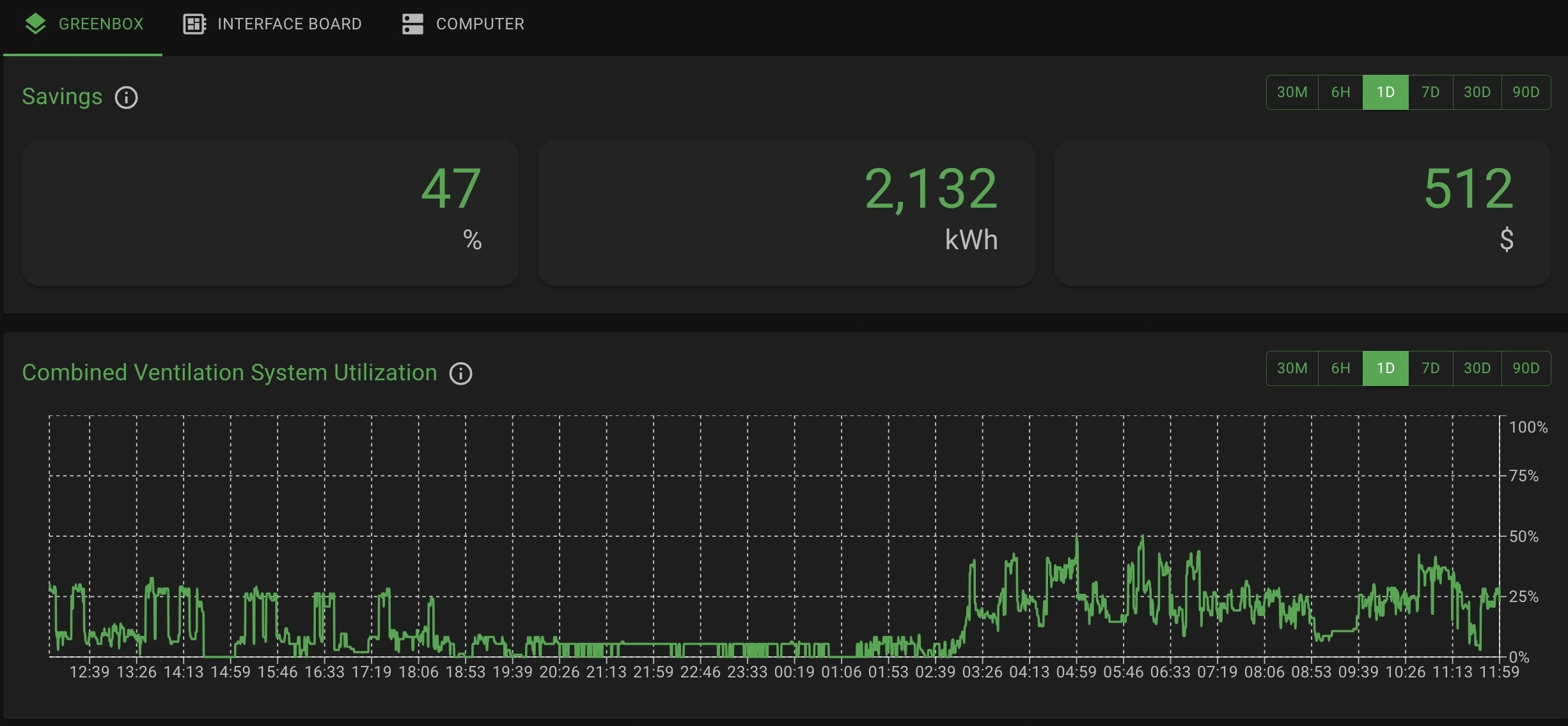

greenBOX Unboxed i2: Electricity Savings Dashboard

- Apr 5

- 5 min

Unveiling the Future of On-Demand Dust Collection: Ecogate's New Generation of Energy-Efficient and Cost-Effective Systems

- Mar 26

- 3 min

Remembering Petr Litomisky: Filmmaker, Inventor, and Ecogate Co-founder