2” Gates for On-demand Central Industrial Vacuum Cleaning Systems

- David

- May 5, 2021

- 3 min read

Updated: May 27, 2025

Introducing Small Gates for Central Industrial Vacuum Systems

We’ve excited to introduce you to small, but durable butterfly gates for industrial vacuum systems. The gates are available in 2" and 3" diameters. To learn more about industrial vacuum systems, check out our article: Ecogate's Central Industrial Vacuum System.

The Design

These gates utilize the same motors as all other Ecogate gates. You can opt for the "standard" motor (a cost-effective choice) or the "smart" motor, which is controllable via Modbus. Smart motors support readings of pressure, air velocity, and air volume. They are equipped with limit switches readable from the control unit (greenBOX), and they measure motor current, supply voltage, and other diagnostic data. The smart motor comes with a pressure transmitter - available in 24" w.c. (6 kPA), 40" w.c. (10 kPa), and 200" w.c. (50 kPa).

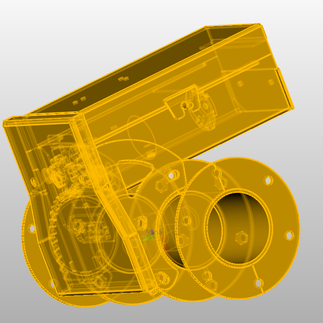

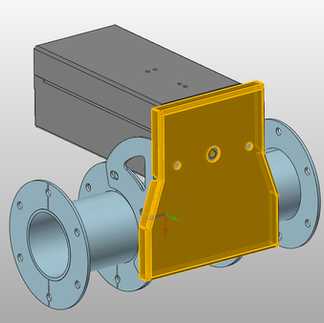

As shown in the drawings, the gate is remarkably compact. Except for the smaller gear, the remaining gate components are the same as those in the larger butterfly gates. Depending on demand, we could design a 3" version (the butterfly gates are currently available from 4" and up).

When to Use a Small 2" Gate

Primarily, this gate is ideal for applications where the material transported doesn't interfere with the butterfly blades. For instance, in pharmaceutical factories. For larger volumes of dust and larger collected material sizes, a rotating blade is more suitable.

The gate is perfect for use when the vacuum system connects to a production machine (e.g., tablet making machine, mixer, etc.). The gate opens when triggered by the machine activity sensor, allowing the vacuum system to start/stop on-demand. This approach can lead to considerable system size reduction and substantial electricity savings!

This gate can also function as a bleed gate. Most vacuum system outlets are simple room outlet ports (valves) that users typically open and connect a hose to for room/workstation cleaning.

How to Maintain Minimum Transport Air Velocity

In on-demand industrial ventilation systems, the greenBOX (control computer) opens additional unused gates to maintain minimum transport air velocity.

However, in central vacuum systems, this method doesn't work because manual room valves are used, and the greenBOX can't open them. Our solution is to install "bleed gates" at strategic locations in all branches of the vacuum system.

If only a few room vacuum drops are open and the air velocity doesn't reach the minimum transport air velocity, the greenBOX will open one or more bleed gates until the minimum transport air velocity is achieved.

The greenBOX Vac Pack

To facilitate a faster, more cost-effective installation of an Ecogate system for Central Industrial Vacuum Systems, we're introducing the greenBOX Vac Pack (EG.408). It allows you to connect sensors from eight room vacuum valves (or eight sensors from workstations connected to the vacuum system) while supporting pressure, air volume, and air velocity measurements.

Summary of Benefits

Implementing the Ecogate greenBOX to manage your central industrial vacuum system can yield significant electricity savings. The greenBOX will maintain minimum transport air velocities, thereby eliminating the risk of dust settling in the duct system. It also facilitates the use of a smaller vacuum pump while managing more room/workstation drops. Notably, the electricity savings will help reduce your company's carbon footprint.

Other advantages include prolonged filter life (if used), decreased compressed air consumption for filter cleaning (if used), reduced system maintenance requirements, and access to a web interface featuring data and analytics about the vacuum system’s performance.

Are you in need of 2” or 3” butterfly gates for your project? Interested in learning more technical details? Don't hesitate to contact us.

Author: Ales Litomisky

Comments