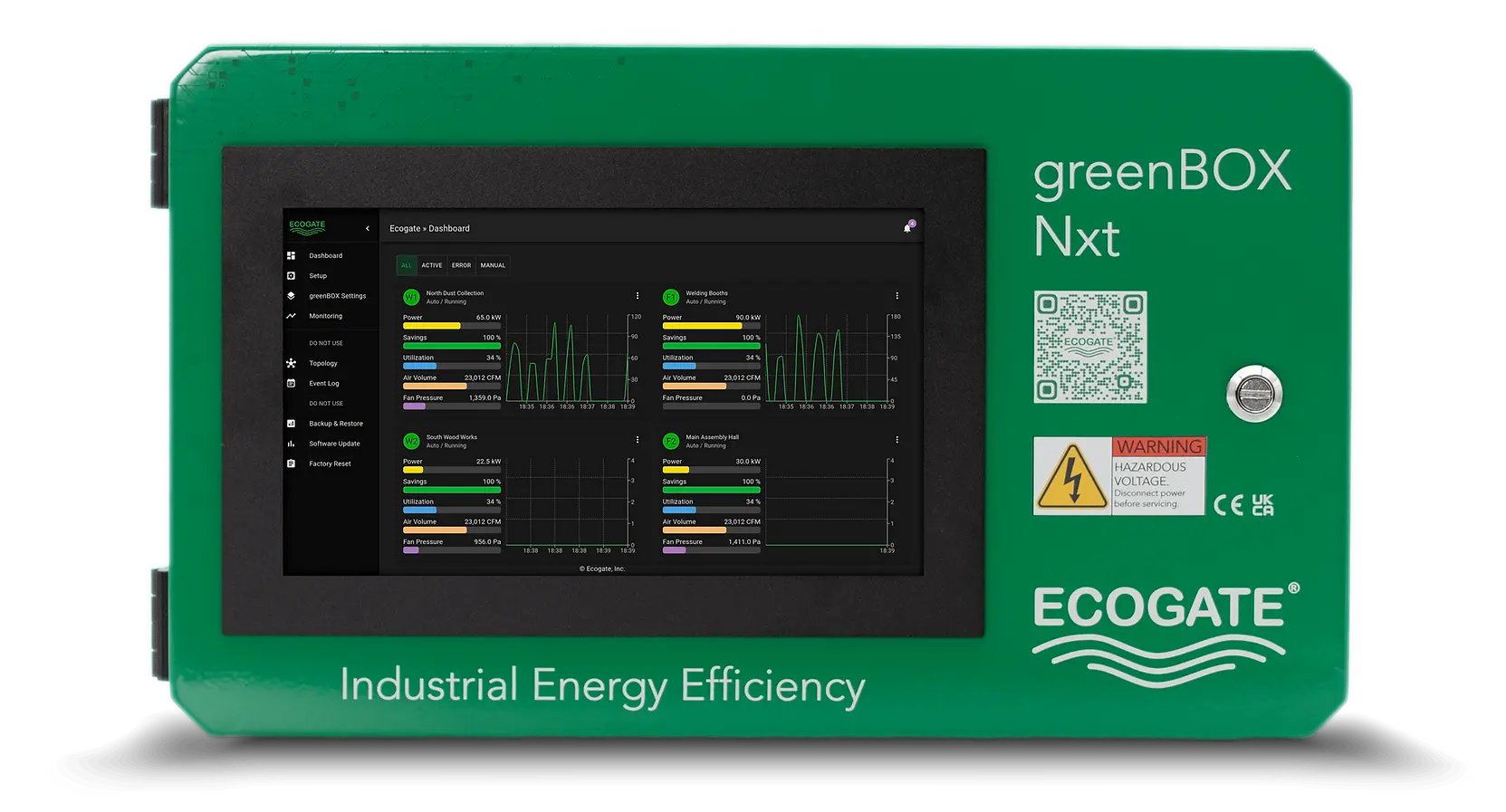

greenBOX Controller

What is an Ecogate greenBOX?

The brain of the Ecogate system, the greenBOX, is a state-of-the-art control unit designed to optimize your dust collection, fume extraction, or mist extraction system resulting in electricity savings of 50% to 75%. The system is designed to be fully automated, so users are expected to just use their workstations.

The greenBOX control unit manages the entire dust collection system: it opens and closes workstation gates, starts and stops ventilation fan(s) and dust collectors, and adjusts the fan(s) speed via Power Master VFD.

greenBOX User Interface

greenBOX Features

Next Unit of Computing with Intel Core Technology

-

Intel 12th and 13th Generation Processors: Equipped with Intel's latest processors, the greenBOX’s industrial computer is powerful enough to manage multiple industrial ventilation systems.

-

Intel NUC Hardware Standard: Utilizes Intel's industrial "Next Unit of Computing" (NUC), selected for its standard physical format making it easily upgradable in future

-

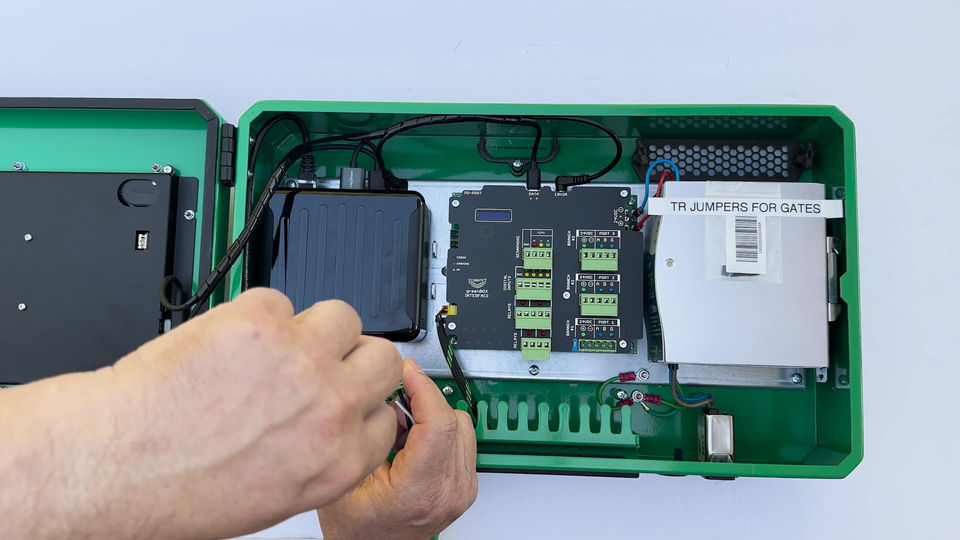

Proprietary Interface Board: Features an in-house designed interface board with RS485 Modbus RTU ports for communication with smart gates and VFDs.

-

Advanced Electronic Fuses: Incorporates user adjustable self-resetting electronic fuses for fast (microseconds) fault response, improving safety and reducing maintenance downtime.

-

Single-Cable Power & Modbus Communication: The greenBOX powers the gates using a single cable that also serves as Modbus communication.

Top Power Supply Efficiency

-

High-Performance Power Supply Redundancy: Seamless operation with dual power supply systems that prevents production halts (available for greenBOX Max and greenBOX Master).

-

Power Supply Efficiency: 24V DC power supply efficiency is 94%, reducing energy consumption while not increasing enclosure temperature.

-

Active Power Factor Correction: Power Supply incorporates active power factor correction, ensuring efficient electricity usage.

-

Exceptional Durability: Boasts an industry-leading MTBF (Mean Time Between Failures) of 1 million hours, guaranteeing minimal downtime and a long-lasting solution.

Safety & Security

-

Minimum Transport Air Velocities: Measures air velocity at the gates, branches and main duct and adjusts in real-time.

-

NFPA Compliant: National Fire Prevention Association mandates that control systems must ensure minimum airflow requirements throughout the entire duct system.

Cutting-Edge Software

-

User Friendly: The software's user experience feels as intuitive as a smartphone.

-

Limitless Capacity: Capable of managing many dust, fume, or mist collection systems–only limited by the power supply capacity for the number of the gates and Modbus ports available.

-

Open-Source Reliability: Runs on Ubuntu Linux, a stable and flexible open-source OS widely used in industrial automation and control systems.

-

Over-the-Air Updates: Uses Mender for delivering over-the-air updates, ensuring OS and application reliability. Features automated rollback in case of update failure.

-

Modular, Containerized Software: Uses Docker for resource-efficient, secure application isolation and quick updates, complemented by ZeroMQ for streamlined inter-module communication.

Data Analytics & Intelligent Integration

-

Workstation Utilization: Continuously collects and analyzes data on electricity savings and workstation activity, enabling month-to-month comparisons and workflow optimization.

-

In-Depth Reporting: Provides a daily email report detailing system performance metrics such as filter losses, fan pressure, air volumes, and velocities, offering insights beyond basic dust collector monitoring.

-

Seamless Integration: Integrates with Higher-Level Control systems (Building Automation System, SCADA, Process Control System) via Modbus Gateway, offering real-time updates on ventilation system performance, warnings, and errors.

Which greenBOX Should You Buy?

We offer four different greenBOX models to meet the needs of various industrial ventilation systems - from small shops up to large factories with multiple systems. Our team of experts can help you determine which greenBOX model is best suited to your specific requirements, ensuring that you get the most out of your investment

Further Reads

Time-Tested greenBOX 12

The greenBOX 12 stands as a proven, cost-effective solution for managing up to 12 workstations. Designed for those who seek both performance and economy, this legacy unit has the capability to maintain minimum airflow in one duct zone and can be paired with the Power Master VFD for fan speed control.

With over twenty years in production, the greenBOX 12 has seen numerous improvements, cementing its reputation for reliability. As part of Ecogate's enduring product lineup, it continues to be the most budget-friendly standard system available in the market. The greenBOX 12 uses Windows PC for setup and for remote access

greenBOX ONE

The Ecogate greenBOX ONE is designed to bridge the gap between an Ecogate Smart System and third-party gates or workstations with built-in gates by the manufacturer.

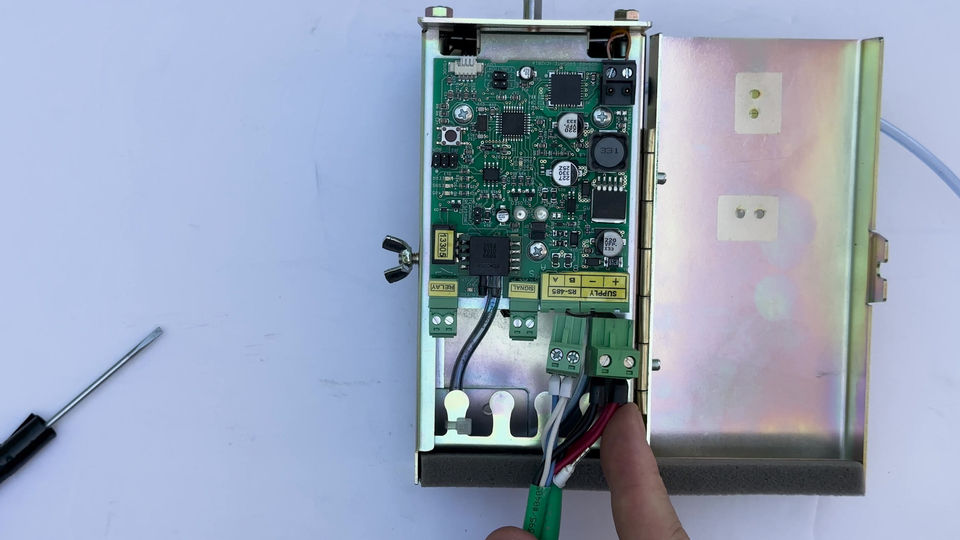

The greenBOX ONE can open/close pneumatically operated or motorized gates if they use 24V DC coils or 24V DC motor (pneumatically operated gates should be equipped with two 24V DC coils, one for opening, and second for closing).

If you have CNC machines with built-in butterfly gates or pneumatically operated automatic blast gates installed in your duct, the greenBOX ONE allows you to integrate them seamlessly with your Ecogate system. The greenBOX ONE serves as an input to the Ecogate smart system, informing it when a particular machine requires ventilation. The greenBOX ONE reads information from the external gate and sends it to your greenBOX controller, which adjusts the fan speed to deliver proper airflow to that specific machine and throughout the system.

With the same pressure sensing tube as Ecogate's Smart Gates, the greenBOX ONE can also read volume, velocity, and pressure at the specific gate, providing advanced control and monitoring capabilities

greenBOX 8

The greenBOX 8, introduced in 1999, was designed to help woodworkers with a dust collection system in their shop reduce their electricity bill. Capable of handling up to 8 workstations, this system provided on-demand ventilation while maintaining appropriate airflow velocities.

The greenBOX 8 is no longer available, as it is now considered 'prehistoric' in the realm of technology development. The great news is that it has been replaced by the newer greenBOX 12, offering even greater flexibility, reliability, and performance.