Modern Dust/Fume/Mist Collection Deserves Modern Software

- David

- May 17, 2023

- 7 min read

Updated: Apr 16, 2025

Listen to this article

All About Software

Marc Andreessen famously declared that software is eating the world back in 2011, a statement that held true then and continues to be accurate today

While this is obvious in many areas of our lives (like the device you’re reading this on!), in others it is less so. Dust, fume, and mist collection is often looked at as a cost center in factories - a necessary price to pay to make useful things. Because of that, the industry has not seen as much innovation as it deserves, with most dust collection systems still running on the same principles as their predecessors 75 years ago.

At Ecogate we believe this is a wasted opportunity. We bring sensors, variable frequency drives, automatic blast gates, and an intelligent controller together to make systems that use 68% less electricity on average (that’s 20% off an entire factory’s electricity bill - over a million bucks saved every year for some of you!) while providing better performance, suction, reduced noise levels, and analytics that allow you to make smart, data-driven decisions.

Here’s a short video that explains how it all works.

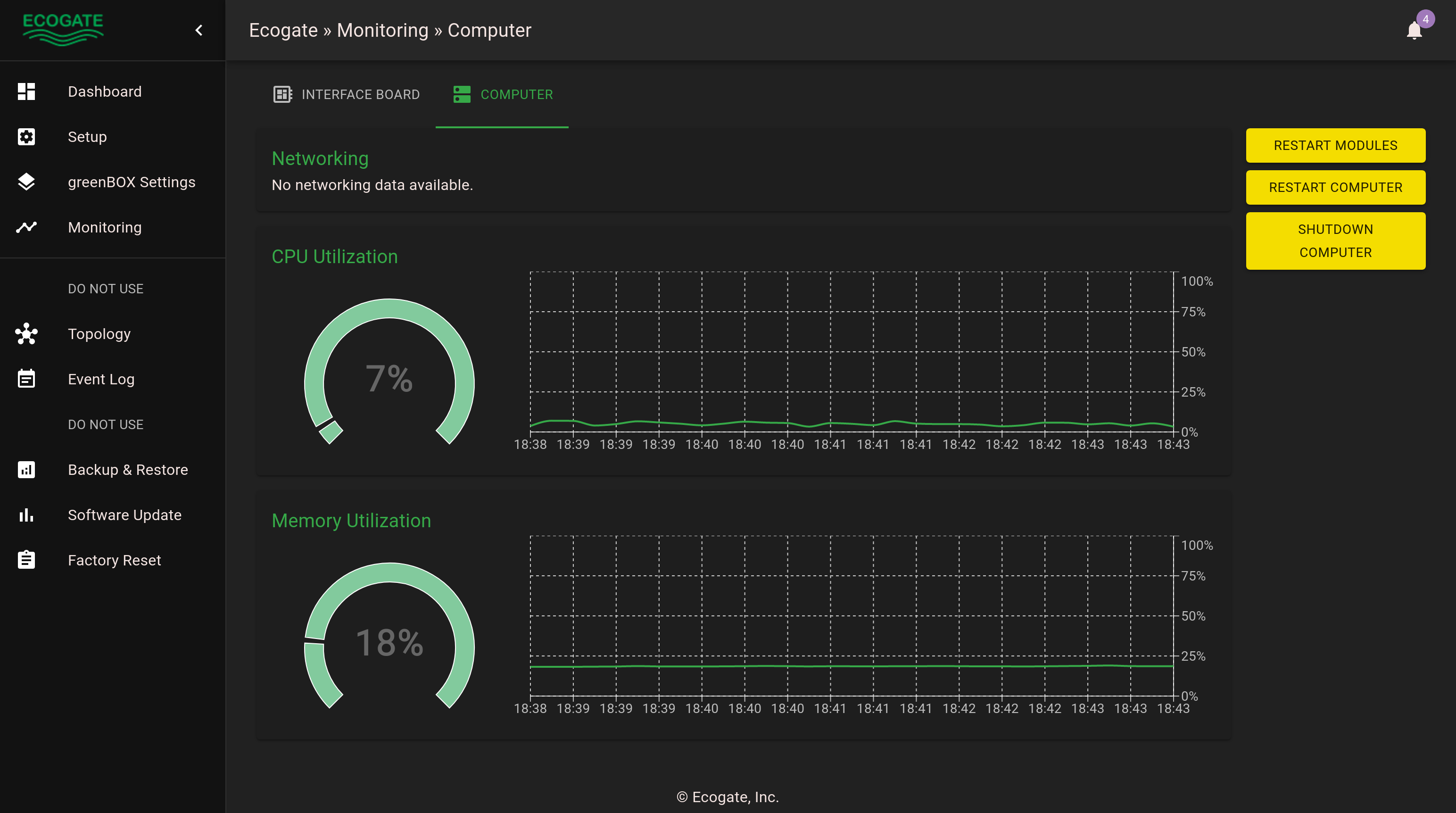

Last week we introduced the 2023 greenBOX Nxt, our new generation controller, marking another significant step forward in Ecogate’s ongoing journey of innovation. Now, let's dive into the software powering this breakthrough.

Best Practices in Software Development

Every year, Google Cloud publishes a “State of DevOps Report” on the best practices in software development and the “organizational and cultural movement that aims to increase software delivery velocity, improve service reliability, and build shared ownership among software stakeholders”. An easy-to-digest summary of a recent report is in this blog post.

We used this data and our team’s extensive experience from solving real-world problems with software to inform every decision we made when building the new greenBOX, and the result is a state-of-the-art controller and architecture.

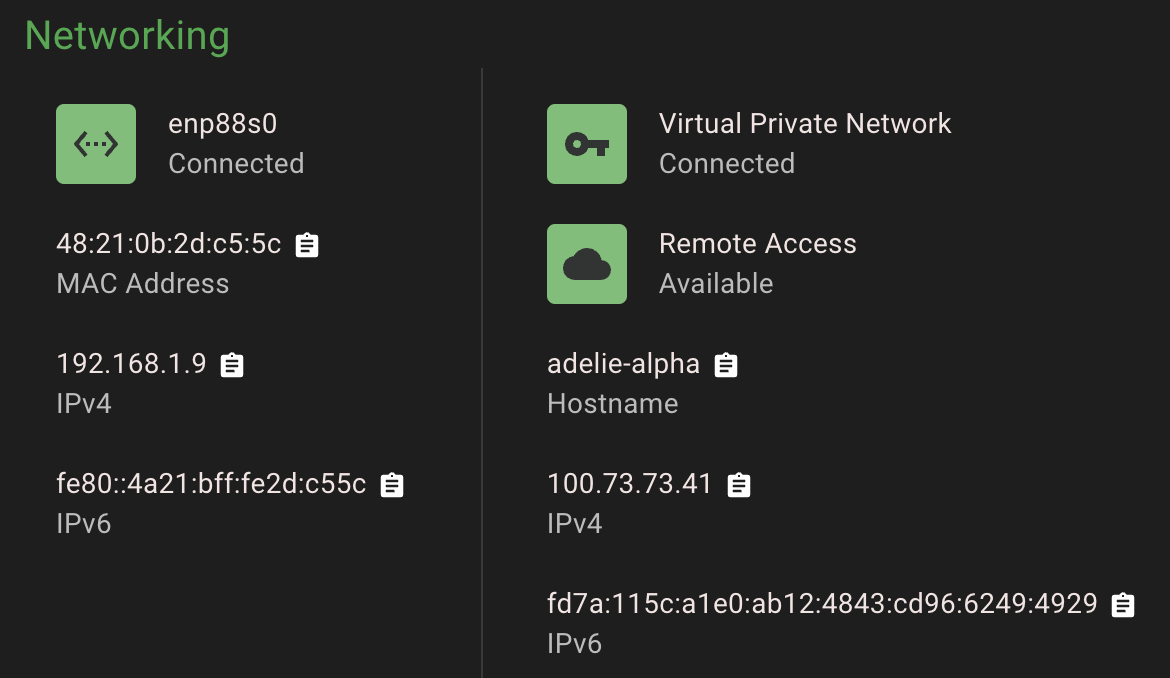

Open Systems and the Adélie Penguin

The greenBOX runs on Ubuntu Linux, the open-source operating system powering much of the world around you. Linux has long been a popular choice for web servers, with an estimated majority of over 70% worldwide. Its stability, flexibility, and open-source nature have also made it increasingly popular in industrial automation, control systems, embedded systems, robotics, and IoT devices.

The Adélie penguin is a species of penguin common along the entire coast of the Antarctic continent, and is the most widespread penguin species. This is why during development the new greenBOX was codenamed “Adélie” - representing Linux's mascot penguin.

We rely on proven open-source software developed by some of the best technology companies in the world throughout our stack.

Everything as a Code, Continuous Integration and Delivery

Common practice for creating the operating systems of industrial controllers is using the “golden image approach”. This is where an engineer hand-configures an operating system instance until things seem to work, and then saves this as an image which is then used as the basis for all future work.

This approach, though, is very manual, slow, and error-prone, ultimately leading often to buggy software where updates are delivered slowly. Any changes or updates to the image must be made manually and then redeployed across all systems. If a security update is released from an upstream source (for example for the operating system or a third-party application), the only way this actually makes its way to the customer is if a software engineer manually pulls in the update on the golden image, and retests everything. For complicated systems with dozens or hundreds of different components, this is never going to work reliably or quickly.

It’s not good enough for us, and it’s not in line with modern software engineering best practices. The current best practice is “everything as code” - instead of manually configuring and managing individual components, such as servers, networks, databases, or infrastructure, the desired state and behavior are defined and expressed as code.

These definitions are then consumed by software that builds your target system. To build the operating system image, for example, we use mkosi from systemd.

The upshot is that when a new security update is released for the operating system, or any third-party application, that update is automatically picked up by our Continuous Integration pipeline, and integrated into a build. That build is then automatically, thoroughly tested, flagging any potential issues well before they may reach a customer build. When our release team decides that it is time to make a software update, it’s one button press, backed by all the thoroughness, predictability, and reliability of automated software builds and testing.

Over-the-air System Updates

Over-the-air updates are delivered by Mender, the open-source system used by industry leaders including Nvidia, Airbus, Siemens, among others.

By using image-based updates, we can guarantee that the operating system and software applications running on the greenBOX are exactly what was validated by our Continuous Integration pipeline. Operating system and application updates are delivered via the same mechanism, increasing predictability and reliability. Mender’s architecture also provides for automated rollback if the update should fail for any reason, providing robustness in the face of power loss, unstable connectivity, or any other issues. There is no unrecoverable bad state and no bricked devices.

Modular, Containerized Software

Our software stack is fully containerized with Docker containers. This helps us make the most efficient use of our computer resources and allows us to update our products quickly. To ensure our software works well, we have automated checks in place that compile and test it automatically, looking for any potential problems.

Containers keep applications separate from each other and from the underlying infrastructure. This makes our applications more secure, stable, and reliable. It also helps us manage complex setups with many interconnected parts.

Containers make it fast and consistent to deploy our applications. We can easily create, deploy, and scale them up or down to handle different workloads.

Containers help us keep track of different versions of our applications and their dependencies. If there's a problem with a new version, we can easily roll back to the previous one. This helps us maintain consistency and reliability throughout the different stages of development.

We use ZeroMQ for communication between software modules. It's a powerful messaging library that offers lightweight and efficient communication for distributed systems and is used by industry leaders including Microsoft, Samsung, and AT&T.

This setup also makes it easy to add new features if they are ever needed. Adding a new module means just adding a new container and connecting it to ZeroMQ - and just like that it is plugged into all the data it needs to do its work.

Browser-based User Interface

We introduced our web browser-based user interface with the original greenBOX Nxt back in 2016, providing a great experience on any device, from your phone to a computer. This has been a hit with our customers, so we are continuing on this path.

Our new user interface is written in React, the open-source framework from Facebook. It is the most popular front-end framework in the world, and therefore is feature-rich and continually updated. This allows us to deliver a user interface experience on par with the best technology companies in the world.

Web-based interfaces are widely appreciated for their flexibility in applications well beyond what you’d think of as traditional web companies - even the SpaceX Dragon capsule has a web-based user interface on the inside.

Security as an Integral Part of the Design Process

Security considerations were a key part of our software architecture design process; everything we do is with security in-mind.

Because we have image-based system updates, we always know exactly what is running on each system. Updates are cryptographically signed and verified.

Our configuration-as-code update process automatically pulls in any security updates as they are released for both the operating system as well as any third-party software.

Data Analytics and Remote Monitoring

Like our previous intelligent controllers, the new greenBOX Nxt continuously collects system data and uploads it to our cloud. The data from your dust collection system is used to generate reports on electricity savings and Active Workstation Utilization (percentage of time spent actively producing). These insights enable month-to-month comparisons and can inform better workflow and factory design.

A daily email for the maintenance manager provides system performance details, including filter losses over time, fan pressure, system air volume, duct air velocities, and drop air velocities at workstations. While other companies offer dust collector monitoring, Ecogate goes further by providing data directly from workstations, ensuring optimal system performance, safety, and health.

Ready For Artificial Intelligence (AI)

The Ecogate software platform for new greenBOX control units is designed to support the implementation of Artificial Intelligence (AI). One day in the not too distant future, you’ll be able to ask your greenBOX what you want in plain language and make requests in the same way.

For example, you might ask, “Is it time to change my dust collector filters?” And the greenBOX might analyze historical data, including pressure seen during operation, and the last time you changed your filters, and the greenBOX might tell you, “It looks like it will be time to change them in about two weeks. Would you like me to order them when it’s time?”

Intelligent and Seamless Integration

One example of what Ecogate systems offer is their intelligent integration with Building Automation Systems or Process Control Systems. Our customers at pharmaceutical factories (GlaxoSmithKline, Upsher-Smith, Fortune Pharmacal), chemical factories (Unilever), and at many universities are using Building Automation Systems (BAS). The BAS can automate the control of multiple building systems, such as HVAC, lighting, safety, and security. Ecogate greenBOX Master allows communication with the BAS.

Featuring a user-friendly interface, the BAS enables end-users to modify settings, monitor system status, and detect potential performance issues. At Ecogate, our installations seamlessly integrate with the BAS, providing updates on ventilation system performance, warnings, and errors. By adjusting your shop's HVAC to replace only the air vented outside through your dust, fume, or mist collection system, you can achieve additional significant savings.

Welcome to Industry 4.0

The new family of greenBOX control units builds on Ecogate’s legacy of engineering excellence to deliver a great solution for our customers.

Our software is state of the art, and has access to data that no one else in the industry has - by installing our sensors on all workstations, talking to the variable frequency drive controlling the fan motor, and connecting to the dust collector, we shed light on what has historically been an opaque area with no information, a dust collection system either on or off, providing no insight into manufacturing operations. We continually optimize the system in real-time based on this data, and provide beautiful summaries every month.

All this cleverness sits in a 'green box' on your wall, working for you day in and day out. The upshot for our customers is dust collection systems that work better, run cleaner and quieter, and use only one third the electricity of conventional (dare we say “dumb”?) dust collection systems.

Welcome to the future.

Authors; Krystof, Marek, and Ales Litomisky

Comments