How Nova Labs Self-Installed an NFPA-Compliant, Right-Sized Dust Collection System

- David

- Jan 14

- 6 min read

When Nova Labs moved into a larger space, they expected to reuse a small-shop playbook or buy a modest turnkey dust collection package. City permitting and the fire marshal had other ideas. Because the shop would run power-fed machines and exceed 5,000 CFM, the jurisdiction required an engineered system that met NFPA 664 (now consolidated into NFPA 660).

It was also the first industrial-size dust collector they had ever reviewed, which meant officials wanted stamped plans and a clear explanation of day-to-day safety. Nova Labs is built around fearless, hands-on learning and entrepreneurship, and the project reflects that ethos.

“Once we established the criteria, Ecogate was a no-brainer.” — Bradley Matthews, Project Manager, Lead Installer, Board Member

Why Ecogate made sense

Nova Labs had seen early Ecogate systems years ago, so automation was already on their radar. Alternatives either felt too industrial and expensive for a makerspace budget, or too hobby-oriented for the scope. The team needed right-sized engineering that would meet code without traditional 100 percent oversizing, and a partner who could help them navigate approvals. At a previous location they ran a five-horsepower collector with manual gates for two tools at a time. Even at that scale manual discipline was hard, which pushed their early research toward automation.

They first submitted an HVAC-designed plan. The city rejected it for lacking required technical detail. It was the first industrial-size dust collector in the jurisdiction, so officials needed extra clarity. With Ecogate engineer Ales producing stamped drawings and joining calls with reviewers, Nova Labs had a performance-based path that met NFPA requirements and satisfied the Authority Having Jurisdiction.

“The city required stamped plans. Ecogate could speak NFPA and help officials understand a performance-based approach.” — Gillian Webb, Project Lead and in-house SME

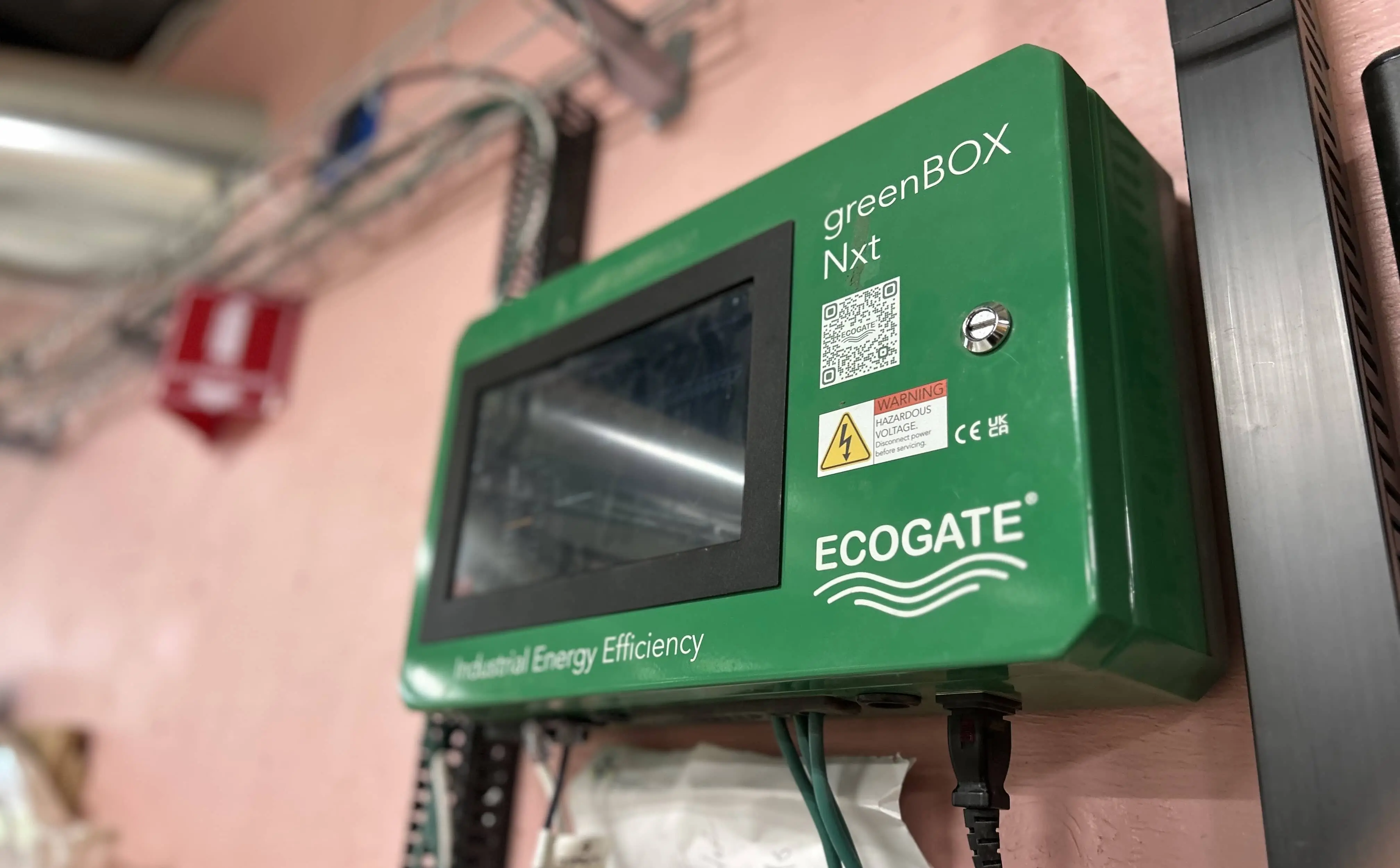

With the greenBOX® control unit coordinating Smart Gates and the Power Master VFD, the system maintains minimum conveying velocity throughout the duct system without oversizing the main.

Right sizing in practice

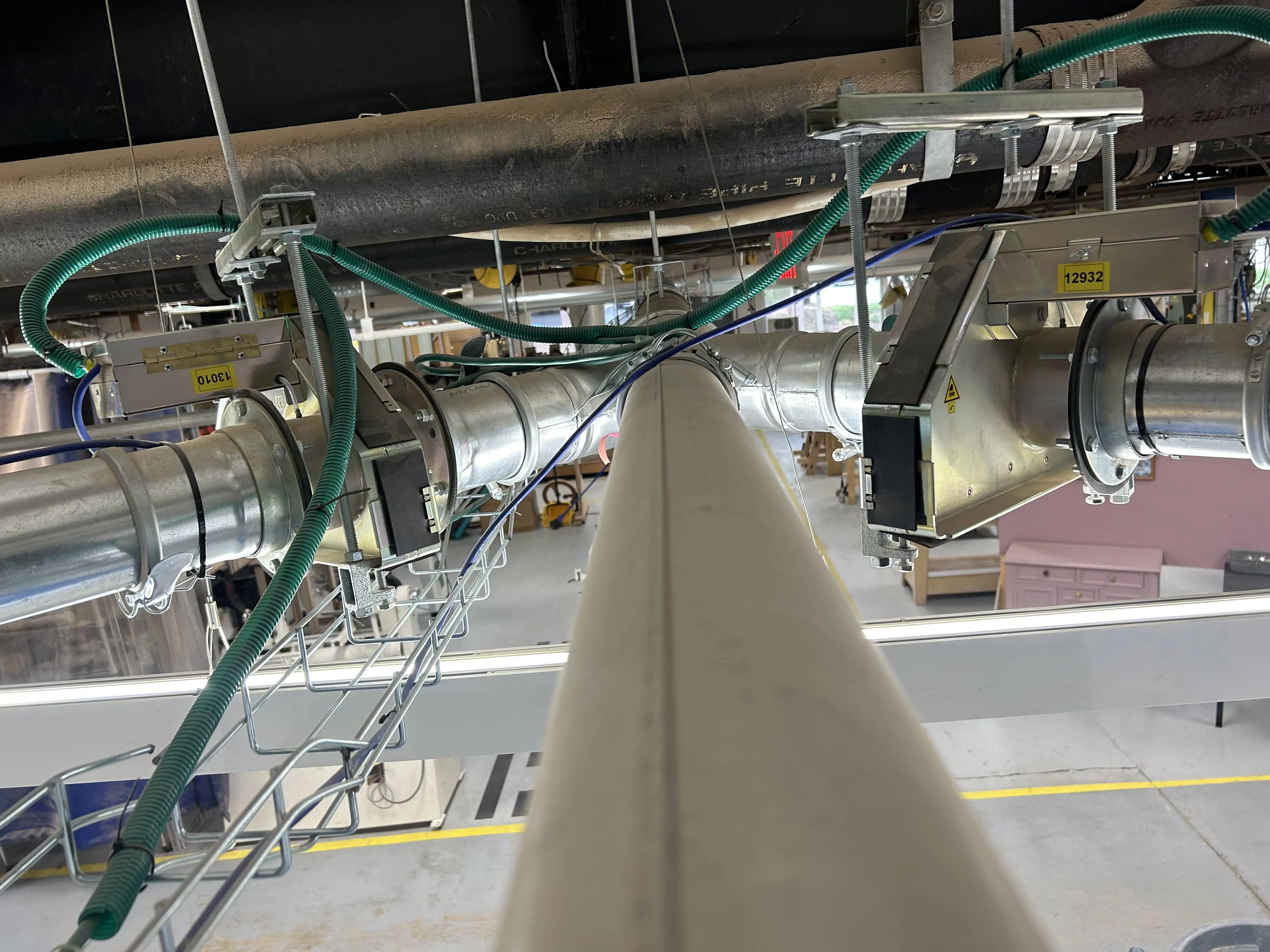

Traditional 100 percent sizing pointed to a very large system. After engineering, the main dropped from 24 inches to 14. Even a partial-load traditional model still landed near twice the capacity they actually needed. Right sizing set the tone for the project: meet NFPA conveying velocity requirements, avoid waste, and keep headroom for growth.

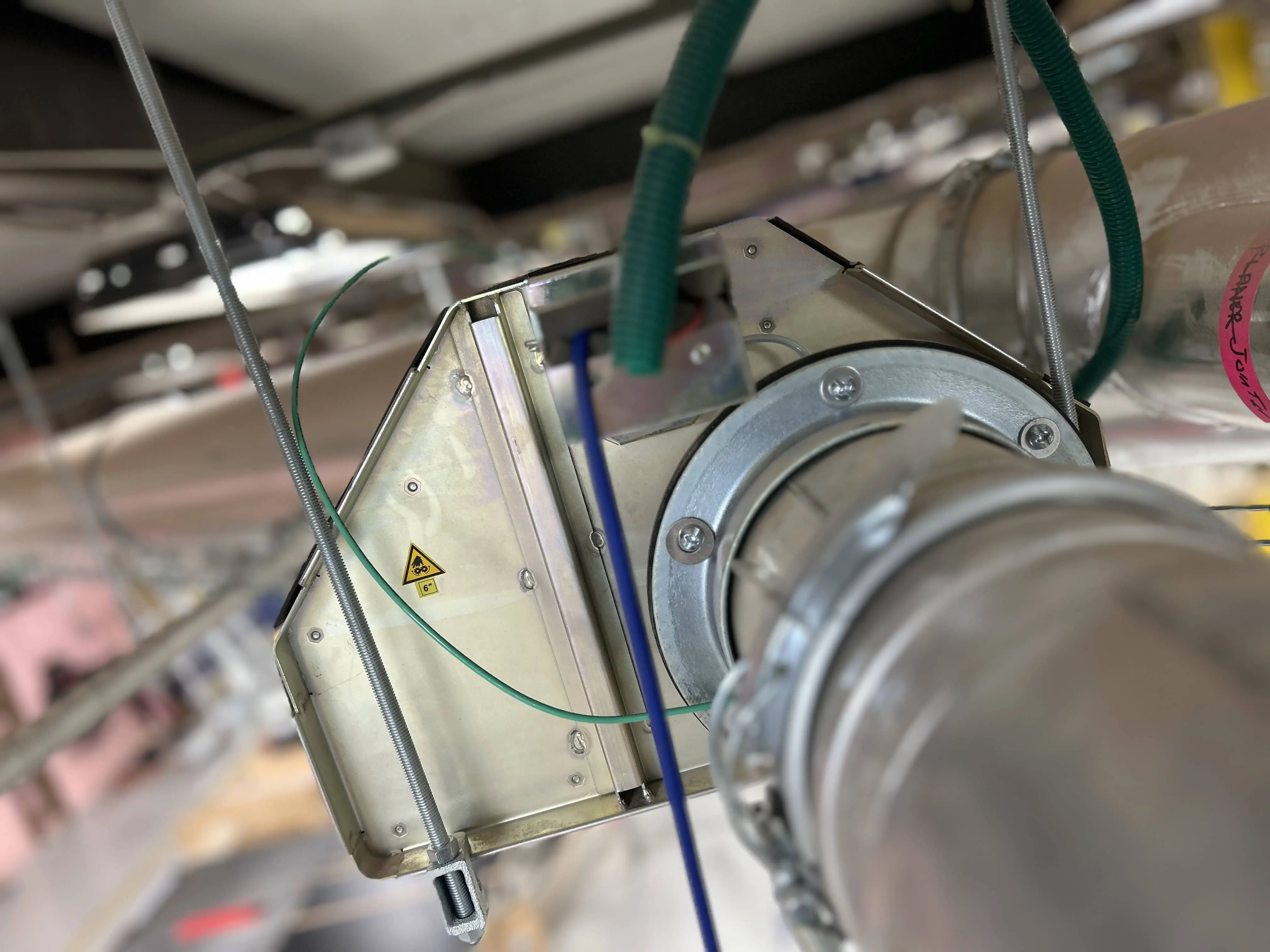

Minor field changes were inevitable: extra elbows in tight corridors, reroutes around walls, and small shifts in drop locations. With traditional systems those adjustments would trigger a full rebalance. Ecogate’s controller automatically compensated, maintaining conveying velocities and letting the install continue without delays.

“We went from a 24-inch main to a 14-inch main.” — Bradley Matthews, Project Manager, Lead Installer, Board Member

A volunteer install that actually worked

Nova Labs executed a full self-install. Volunteers handled duct layout, mechanicals, electrical, gate installation, and controls, with Ecogate commissioning at the end. They sourced clamp-together ducting in three primary shipments plus a few small follow-ups as the layout evolved. Five-foot sections let weekend crews move fast, so main trunks went up in a few weekends before the team shifted to drops.

The project ran about nine months and approached ten thousand volunteer hours. Most volunteers handled repeatable mechanical tasks like strut and hangers, while a smaller group with panel experience took on electrical and controls. They even produced their own duct takeoff after quotes came back inconsistent with the evolving layout.

“Smart control gave us the freedom to make field adjustments. The system just handled it.” — Gillian Webb, Project Lead and in-house SME

A key reason this worked is that the architecture is installer-friendly and modular. Smart Gates communicate on a single Modbus RS-485 daisy chain, and Power Master configuration is straightforward, which kept complexity down without compromising code compliance.

The price tag

Cost is where the story gets interesting. A turnkey package was quoted near one million for this scope. By self-installing and focusing on a right-sized design, Nova Labs spent about one hundred fifty thousand total, including Ecogate.

“We spent about one hundred fifty thousand total instead of near a million by self-installing.” — Gillian Webb, Project Lead and in-house SME

Always improving

Ecogate’s R&D process is driven by real-world feedback. Our engineers are constantly listening to customers and turning their insights into updates that improve daily operation. Nova Labs contributed thoughtful suggestions during their install, such as easier daisy-chain terminations and a simple visual “ready” indicator for gates mounted high.

For Nova Labs, these were minor notes on a system they describe as robust, flexible, and easy to adapt. For Ecogate, they are the foundation of continuous improvement.

What comes next at Nova Labs

Next steps are straightforward. Finish two deferred drops and floor sweeps, then add fifteen to twenty gates as utilization grows. On-demand fume collection will come online as the metal shop scales beyond portable units.

In parallel, they are planning a lab-grade fume exhaust for small lasers, resins, and jewelry work, with a high-plume discharge to keep odors out of occupied spaces and away from neighbors. On controls and data, they are interested in Ecogate HMI options, Dust Collector Controller integration, and tying system data into their tool-access control so usage and extraction stay in lockstep.

Fast facts

Total spend about $150,000 vs near $1,000,000 turnkey

Main reduced from 24 inches to 14 inches

About nine months and about ten thousand volunteer hours

NFPA 664 accepted by city and fire marshal

Ready to add 15 to 20 gates without heavy redesign

About Nova Labs

Nova Labs is a nonprofit makerspace in Fairfax, Virginia, with a 20,000-square-foot facility designed for innovation, education, and collaboration. Members gain access to advanced tools in woodworking, metalworking, machining, electronics, and digital fabrication, supported by expert training and a culture of fearless, hands-on learning.

Beyond member projects, Nova Labs runs Makerschool programs for K–12 students, summer camps, after-school enrichment, and youth robotics, ensuring the next generation of makers has access to skills and mentorship.

Operating as a 501(c)(3), Nova Labs thrives on community support, volunteer leadership, and partnerships, creating an environment where entrepreneurs, artisans, and hobbyists can bring ideas to life.

Thinking about right-sizing your own system?

If your facility is facing compliance requirements or you want to avoid oversizing, start a conversation with an Ecogate engineer about right-sizing and performance-based compliance. We can review your plans, talk through requirements, and help you scope a system that fits your workloads and budget.

FAQs

Why did Nova Labs need an engineered dust collection system instead of a small-shop setup?Because the new shop exceeded 5,000 CFM and used power-fed machines, the AHJ required an engineered design with stamped plans and NFPA combustible-dust compliance documentation.

What NFPA standard applies to woodworking dust collection systems today?Requirements commonly referenced as NFPA 664 have been consolidated into NFPA 660. Many AHJs still reference 664, but NFPA 660 is the consolidated standard.

What does right-sizing mean for a dust collection system?Right-sizing means engineering the system for actual simultaneous demand and minimum conveying velocity requirements, rather than assuming every drop runs at once.

How can an on-demand system reduce airflow and still keep duct velocities safe?Only the gates serving active tools open, and fan speed adjusts in real time. The controller manages airflow distribution to maintain minimum conveying velocity where required while avoiding unnecessary total airflow.

If duct routing changes during install, does the system need to be manually rebalanced?Static systems often require rebalancing because they assume fixed conditions. On-demand systems adjust dynamically by controlling gates and fan speed based on real operating conditions.

Why did the main duct diameter drop from 24 inches to 14 inches?A 24-inch main reflected a 100 percent open assumption. Engineering for actual demand and conveying velocity targets can reduce main size while still meeting performance and compliance constraints.

Does this case study claim every shop can go from a million-dollar quote to $150,000?No. That comparison reflects Nova Labs’ specific scope and a volunteer-led self-install. Turnkey pricing varies based on duct complexity, collector selection, permitting, and labor.

Can the system expand later without major redesign?Yes, when expansion is planned into the original engineering. Nova Labs expects to add 15 to 20 additional gates as utilization grows.

What should a facility prepare before talking to Ecogate about right-sizing and compliance?A tool list, estimated simultaneous usage, collector details, layout constraints, and AHJ requirements are the most useful starting inputs.

Comments